Products

Mesh is our passion.

We call it Universal Space Mesh (USM)

Our products & Services

Variants of mesh out of different core wire materials.

Datasheets

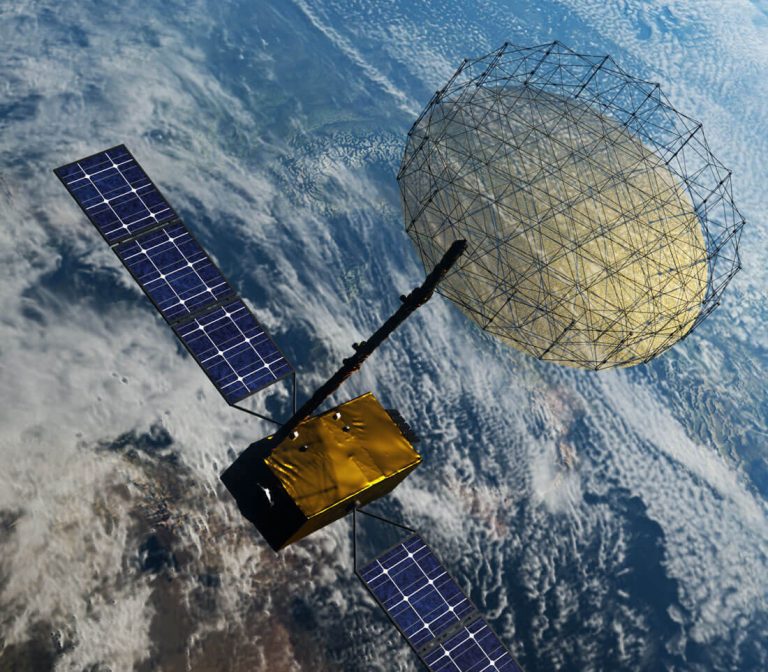

As high conductivity is essential for good RF-reflectivity, reflective surfaces made with our USM are perfectly suited for reflector antennas, for both with deployable- and shell-reflectors.

Applications in space range from telecommunications to earth observation, from L- to Ka- and even up to V-band. Terrestrial use include portable and lightweight ground antennas.

We are even investigating possibilities to introduce products that serve as shields against electro-magnetic radiation.

Our products provide best possible balance between RF performance and mechanical elasticity.

We offer both, well defined products with fix characteristics off the shelf and customized ones to meet specific customer needs. In case of need, batch related characterisation tests (RF, mechanical, thermo-optical, etc.) can be performed on request.

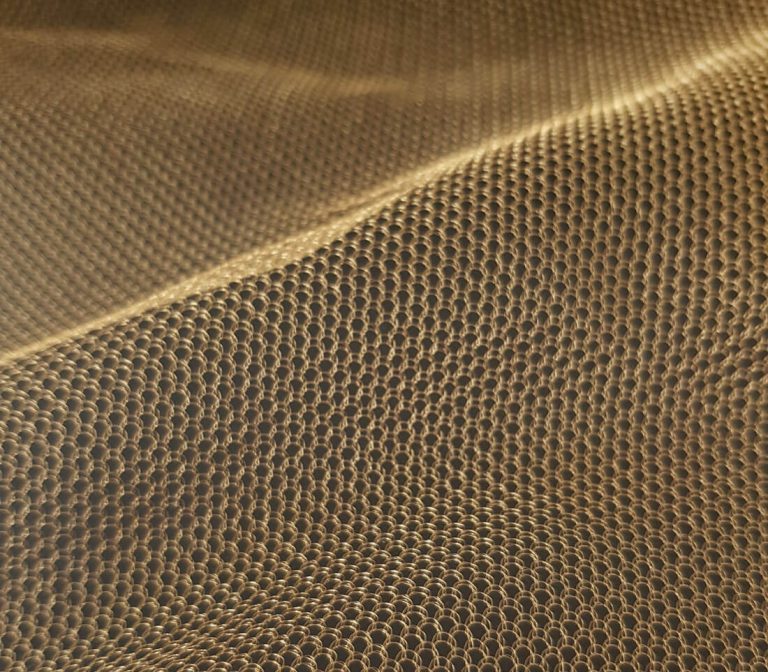

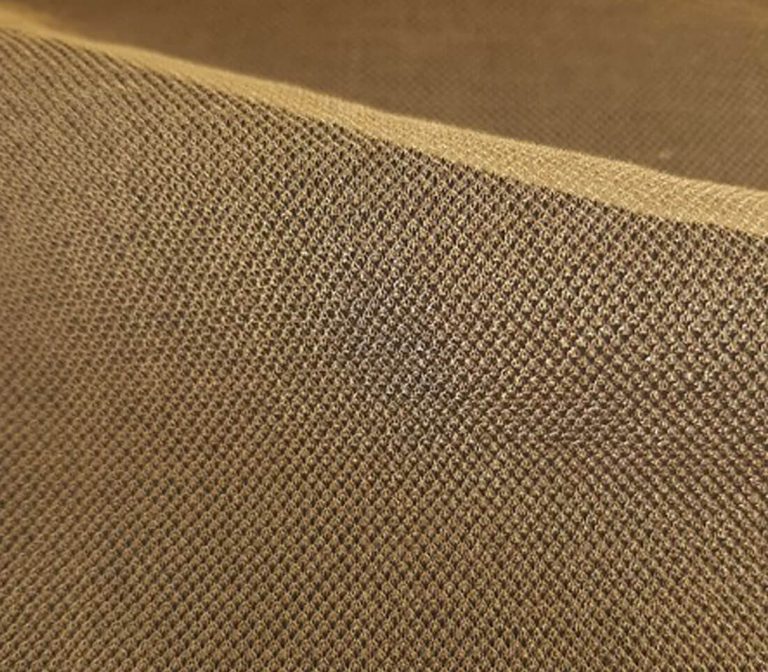

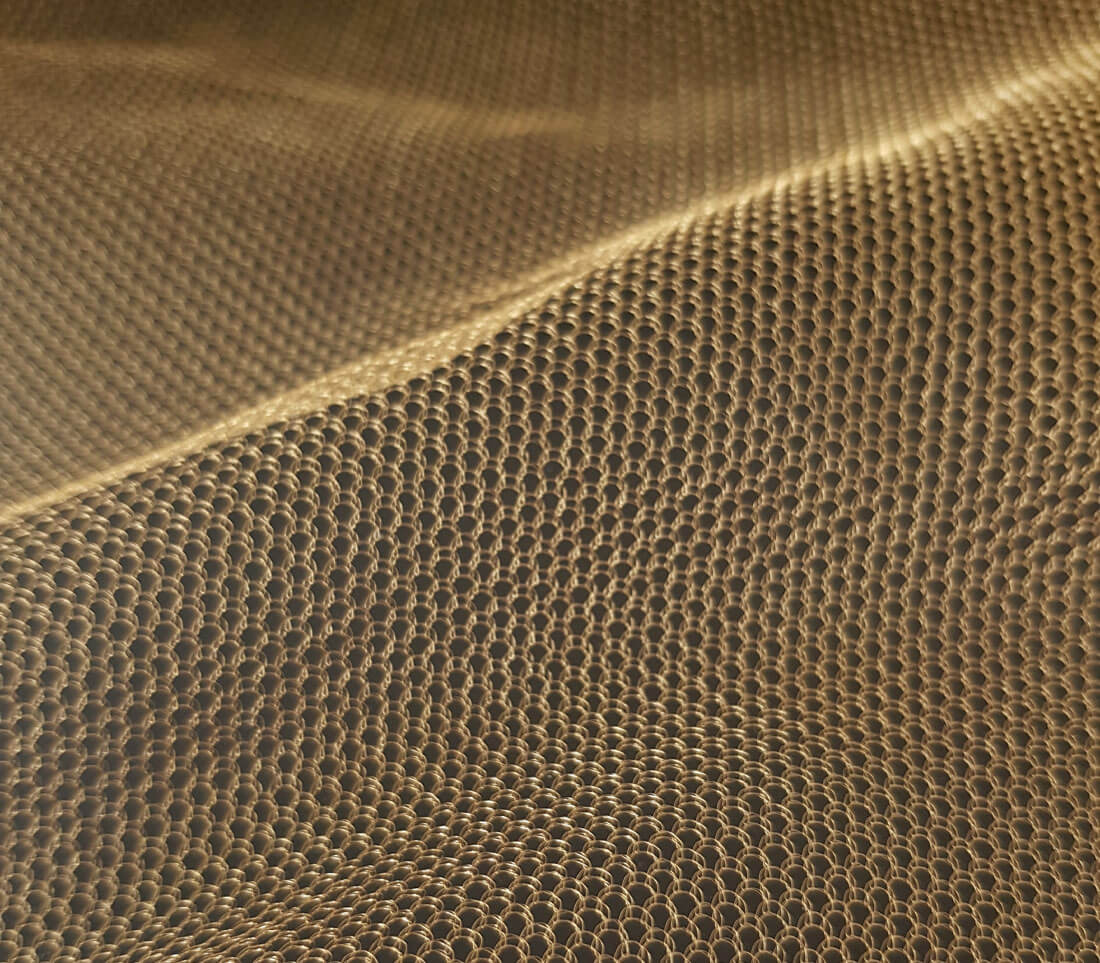

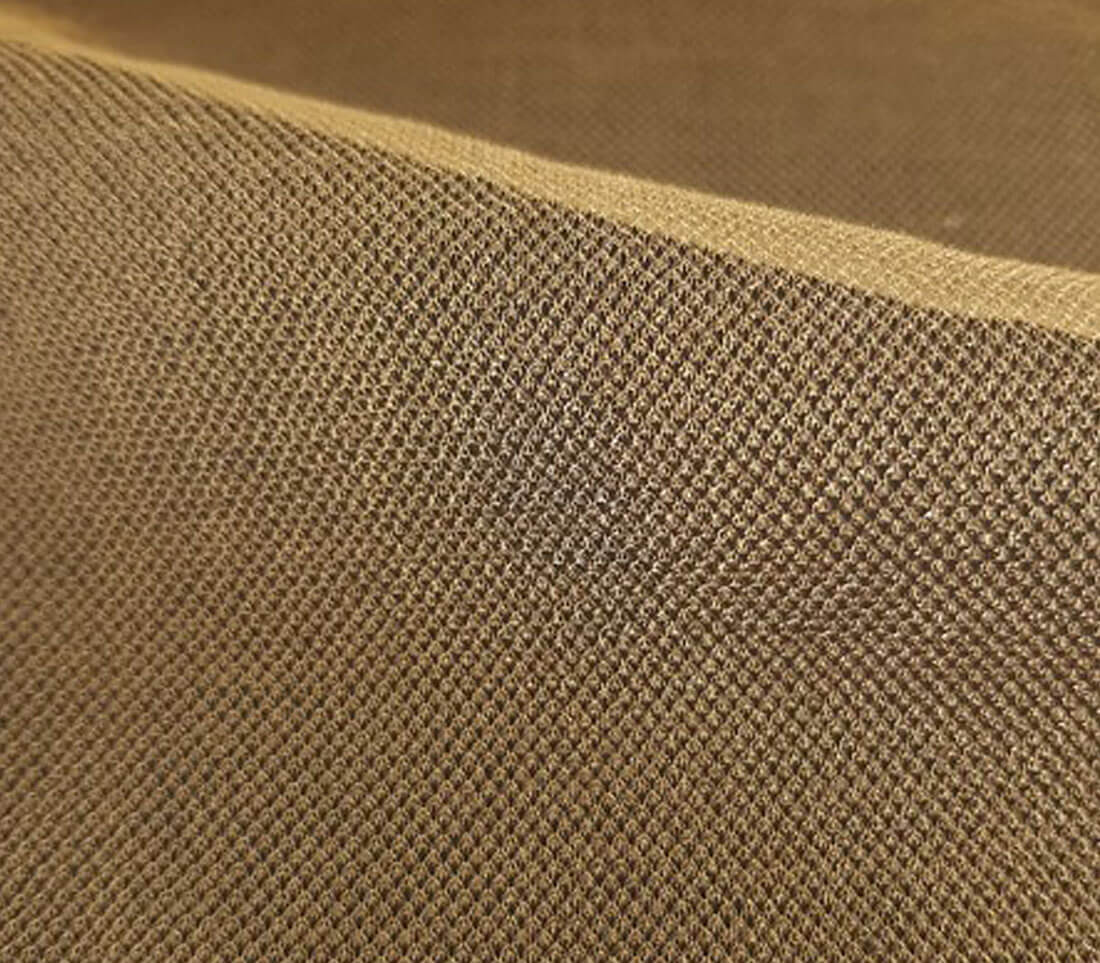

The reflective surface is typically composed of a very delicate technical fabric, manufactured by a warp knitting machine. Single ultra-thin gold-plated metallic wires are used as basic material of our warp knitted metallic fabric. Different frequency bands are satisfied by different mesh densities.

Two further characteristics of our USM are:

a) The weight of the fabric needs is always targeted to be as low as possible.

b) The wire material in use provides an optimum of electric conductivity and is able to withstand both very low and very high temperatures when the reflector antenna is exposed to the sun or to some possible shadow conditions in the orbit such as an eclipse.

Out of the multitude of technical textiles, warp knitted fabrics are the ones with the properties best suited for reflector surfaces. Several variants of mesh made out of different core wire materials such as tungsten or molybdenium are availiable.

The wire diameters depending on the applications range from 20µm to 30µm.

The differences in the mesh coatings materialize through different plating thicknesses and are for example made of gold. The manufactured mesh has outstanding drapability properties which allow to form a perfectly parabolic reflector shape.

The warp knitting patterns like the two main ones called ATLAS and TUCH are commonly used nowadays for reflectors, since they have the best properties in terms of drapability and RF reflectivity.

Up-to-C-Band Mesh

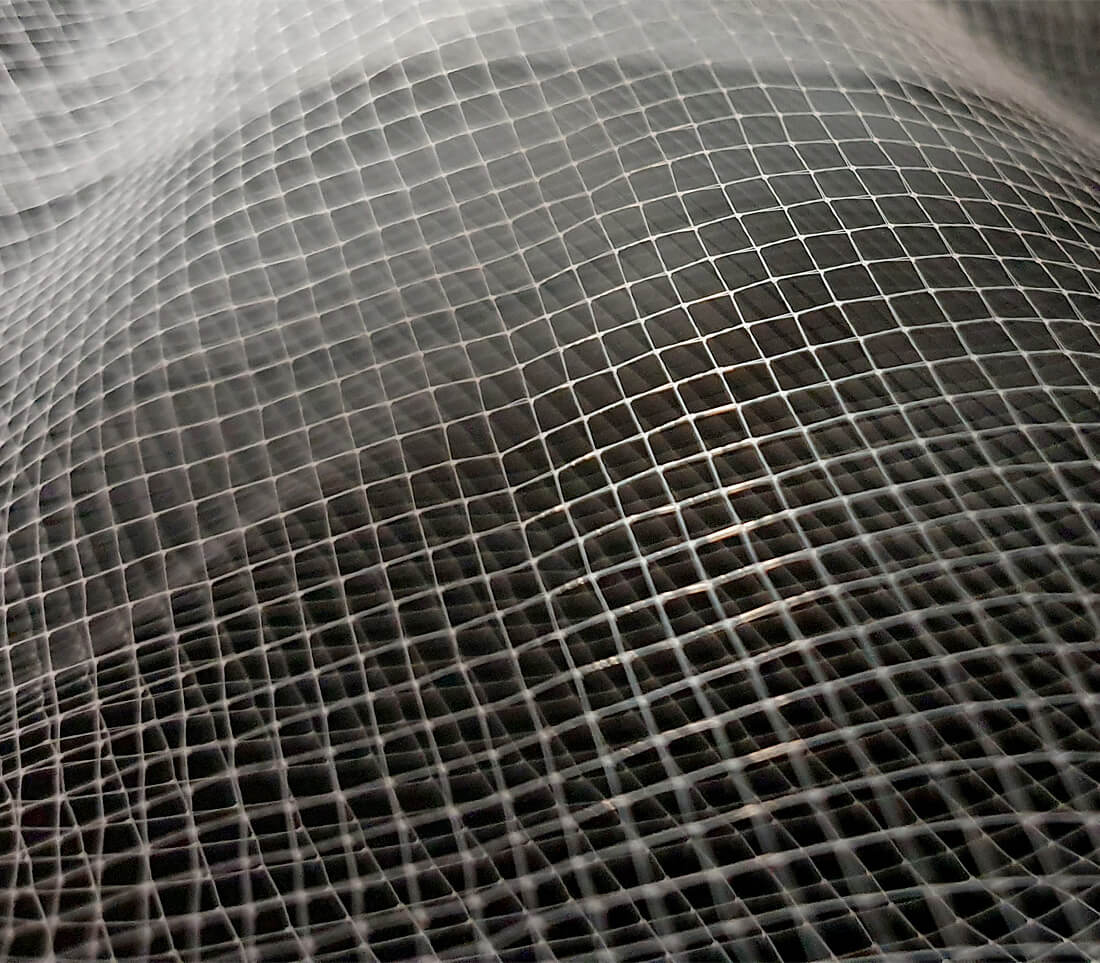

Are mainly used for very large earth observation antennas. Our USM here is characterized by relatively low density and very high elasticity. It can be used also for lower frequencies such as UHF. Advantages are very attractive prices due to lower material costs and to simpler warp knitting machine configuration needs.

Currently one specific product is available from our portfolio (see table below). Other configurations (wire-material/-thickness/-coating, warp knitting pattern, density) can be provided on request.

Product Information

| USM-ATLAS16 | |

|---|---|

| Application Frequencies: | C-band and lower |

| Wire Material: | Molybdenum, gold plated |

| Warp Knitting Pattern: | ATLAS |

| Available width: | 4.5m |

C-to-ku-band mesh

Ku-band mesh is most commonly used for earth observation antennas as well as for telecommunications missions. The respective USM is characterized by relatively medium density coupled with reasonable elasticity. It can be used also for lower frequencies such as C-band.

Currently two specific products are available from our portfolio (see table below). Other configurations (wire-material/-thickness/-coating, warp knitting pattern, density) can be provided on request.

Product Information

| USM-ATLAS32 | USM-ripstop32 | |

|---|---|---|

| (for high elasticity) | (for good RF performance) | |

| Application Frequencies: | C to Ku-band and lower | C to Ku-band and lower |

| Wire Material: | Molybdenum, gold plated | Molybdenum, gold plated |

| Warp Knitting Pattern: | ATLAS | Ripstop-Atlas |

| Available width/length: | 4.5m | 4.5m |

Ku-to-ka-band mesh

Highest reflectivity of the USM-Tuch32 is a “must” when it comes to telecommunications antennas, same applies to very specific earth observation missions (such as the Copernicus Mission CIMR). The Ka-band mesh is characterized by relatively high density at moderate elasticity. It can be used also for lower frequencies such as K-/Ku-band. The manufacturing of such meshes is quite demanding due to the need for hundreds of wires feeding our warp knitting machines simultaneously.

Product Information

| USM-TUCH32 | |

|---|---|

| Application Frequencies: | Ka-band, and lower |

| Wire Material: |

Molybdenum, gold plated Tungsten, gold plated |

| Warp Knitting Pattern: | TUCH |

| Available width/length: | 4.5m |

V-Band Mesh

Our most outstanding development challenge currently is a mesh for V-band telecommunications antennas. It is characterized by extremely high densities while still providing specific elasticity. Manufacturing this type of mesh requires highly sophisticated configurations for the production machines.

Currently several configurations (wire-material/-thickness/-coating, warp knitting pattern, density) are under investigation under ESA contract. A first qualified product is expected by end 2025.

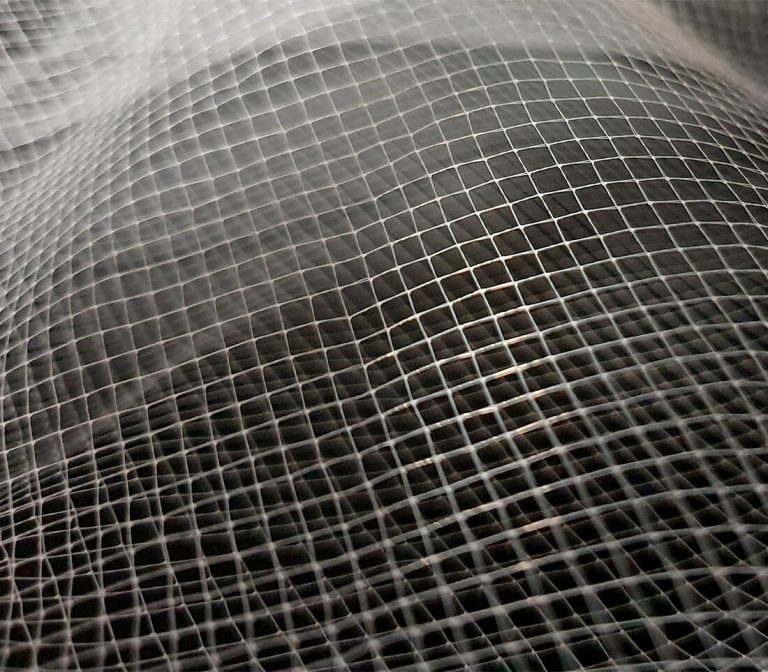

USM-Steel

Training Mesh

The new HPtex stainless steel mesh is the perfect complement to the gold-coated, highly reflective functional meshes in the HPtex product range. All available gold mesh types can be ordered as training mesh in stainless steel.

USM-STEEL mesh is ideal for simulating handling and functional tests.

With USM-STEEL mesh, HPtex offers its customers an inexpensive training mesh with perfect mechanical properties.

We offer this mesh as a customized product.

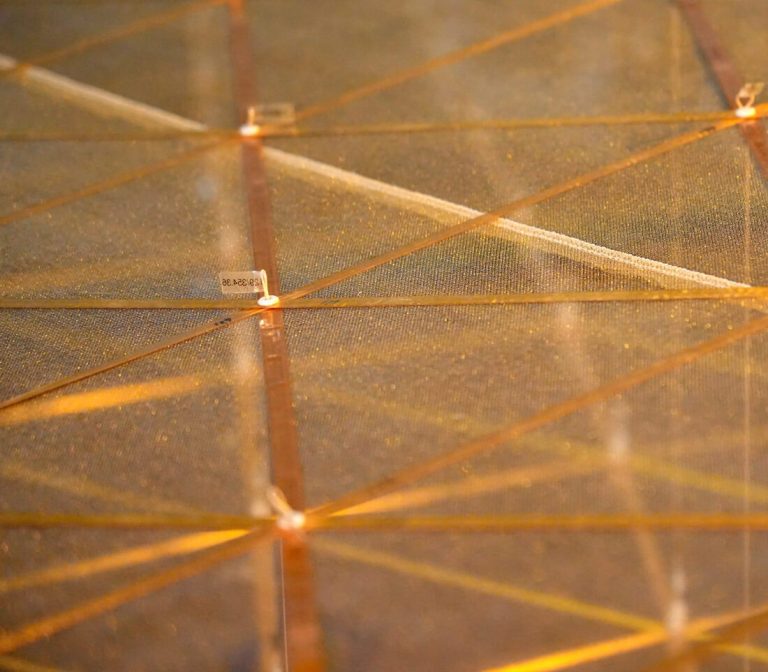

Mesh-Sewing

Sewing

The HPtex-ASM (automatic sewing machine) sewing unit was specially developed by HPtex for sewing metallic mesh strips.

With electronically controlled drive units and laser measurement, it is possible to sew up to 3 mesh stripes together automatically and without distortion. The seam used is self-locking and elastic. The sewing material used meets the requirements of space applications.

HPtex can sew all mesh types offered for sale on request.

| Number of single mesh stripes: | 2-3 |

| Possible single stripe widths: | 50cm - 330cm |

| Possible single stripe lengths: | up to 15m |

| Possible mesh types: | all meshes available from HPtex |

| Possible materials: | metal meshes, plastics and natural fibers |

MLI-Spacer

Spacer P‐M‐11 and ‐13

| Type M‐11 Mass per area: | < 14 g/m² (For MLIs with many folding or application in gabs to avoid the risk of contact between the foils.) |

| Type M‐13 Mass per area: | < 7 g/m² (The best compromise between weight, handling and performance.) |

| Thickness: | < 0.3mm |

| Material: | Polyester |

| Temperature Range: | up to 120°C |

| Mesh width up to: | 1.2m (for wider size, pls. contact us) |

| Cleanliness class: | Cleanliness class ISO 8 (for better classes, pls. contact us) |

| Outgassing values: | Outgassing values TML < 1% , CCV < 0.1% |