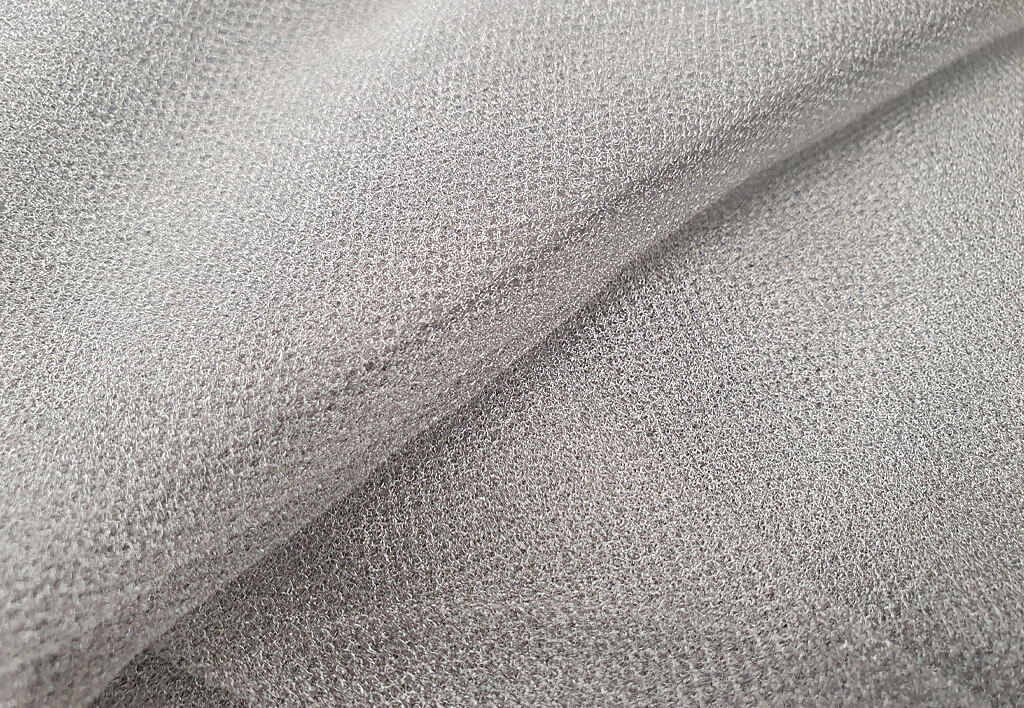

Size matters – there are different opinions about this motto depending on the context. As far as the production of MESH is concerned, however, there are no dissenting voices. Why? With the size of the reflector in space, the economic efficiency of the deployment technology itself simply increases in direct proportion: the larger deployable antennas can be built at all, the greater the application benefit with simultaneously decreasing transport costs. Until now, however, the insurmountable limit for MESH products from a single mold was already at reflectors of 6.5 meters in width. And it is precisely at this point that HPtex now plays out its unique advantage with the ability to sew two to three individual mesh webs with a maximum individual width of 3.4 m. fully automatically and without distortion. The maximum web length is 15m. so that HPtex can now also supply its customers with a ready-made mesh of up to 10 x 15m. Both gold mesh and stainless steel mesh can be sewn according to atlas and cloth patterns. The resulting seam is self-locking and elastic, ensuring good stretchability of the product.

HPtex CEO Peter Rauhut:” Nobody in the world operates a warp knitting machine for mesh over 6.5m. The norm is 132-inch machines, but with a width of 4.5 meters, we at HPtex are already the lone exception. The ability to now also sew webs fully automatically into even much larger products is now another building block of our worldwide unique position.”